Project Process and Manufacturing Flow

Concept Study

- Bullet Points layout and study.

- Develop structures required.

- Develop product specs and test requirements.

Cosmetic & Mechanical Design

Computer-aided Cosmetic design

Preliminary feasibility study

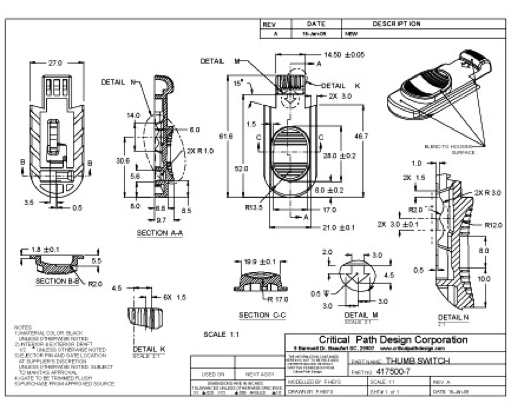

Mechanical Drawings(Pro-E)

Customer Approval

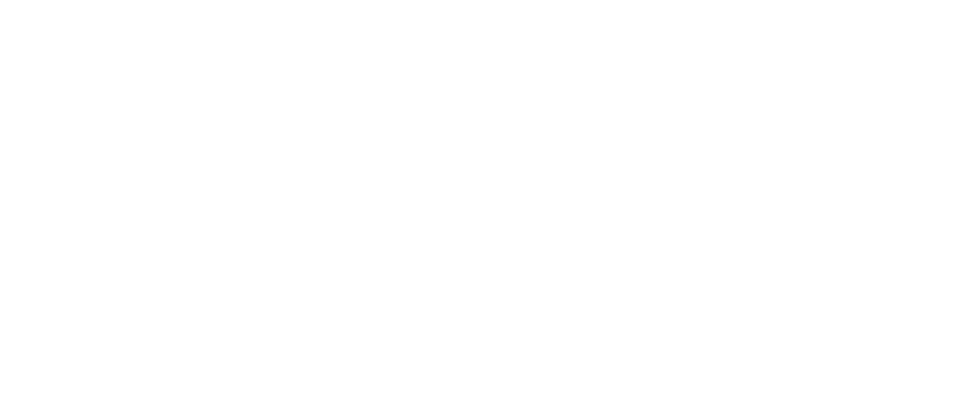

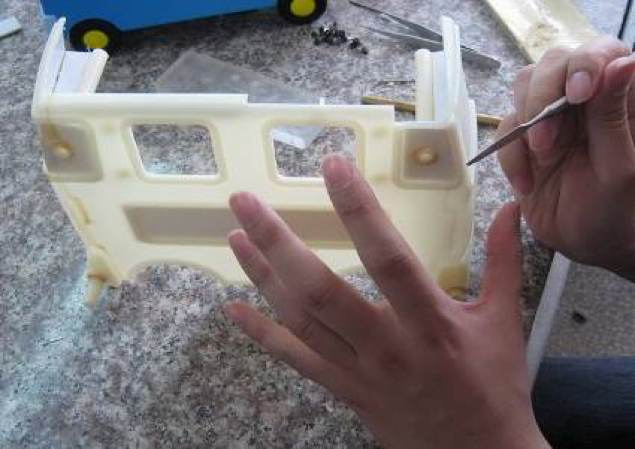

Prototype Fabrication

- Machine all parts according to drawings

- Follow-up machining and Handwork

- Add Electronic parts

- Prototype Decorations

- Customer approval of Prototype

- Follow-up machining and Handwork

- Add Electronic parts

Prototype Decorations

Customer approval of Prototype

Finalize Design

Three Elements of significance--

- Technically feasible

- Ease of manufacture

- Best Cost/Value

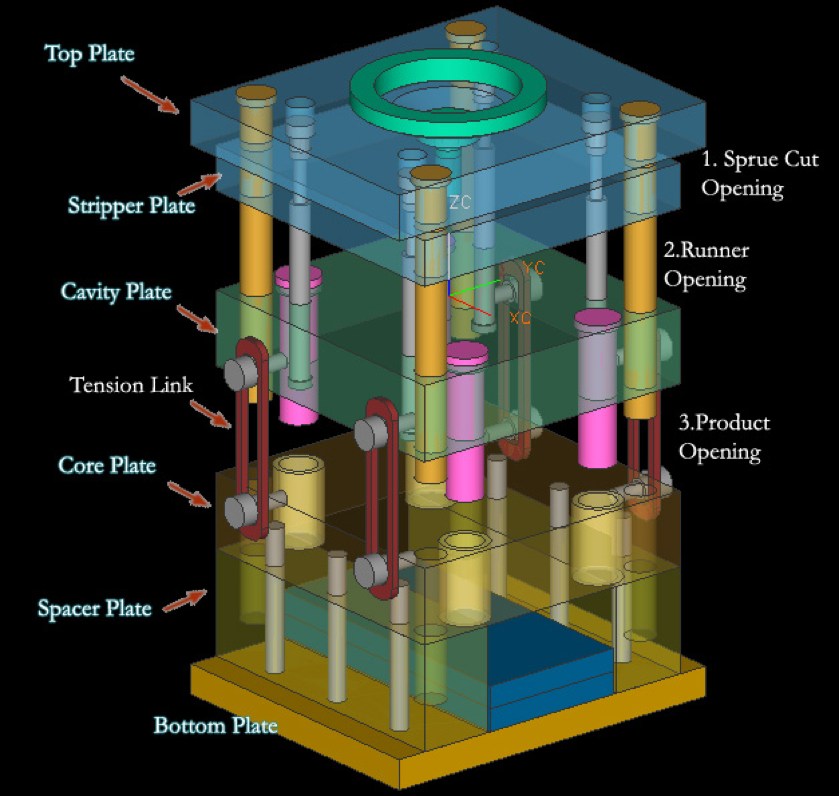

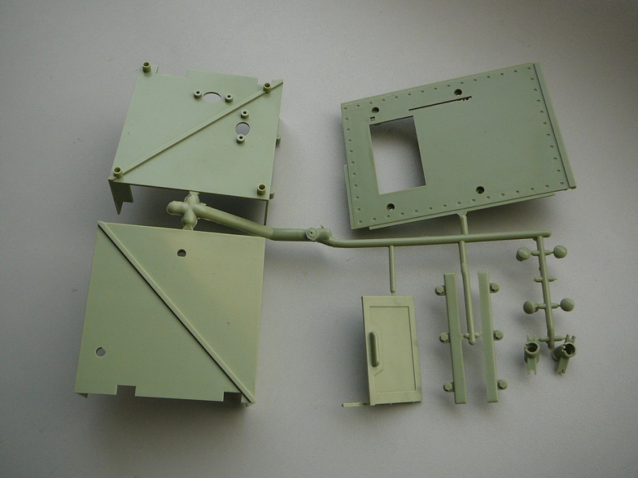

MOLD Design

- Mould Construction Design

Mold CAD Drawings

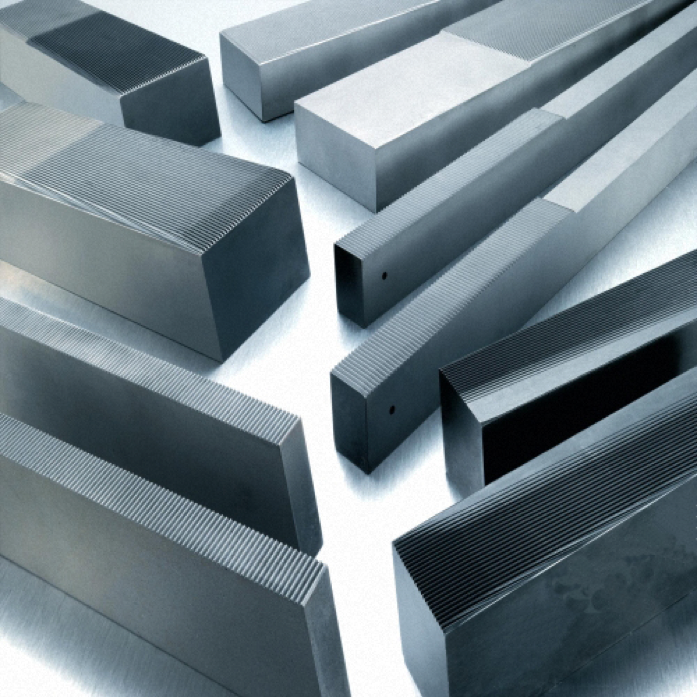

Selection of materials for the mold (e.g. Steel selection:718H, S136H,P20...).

Mold Fabrication

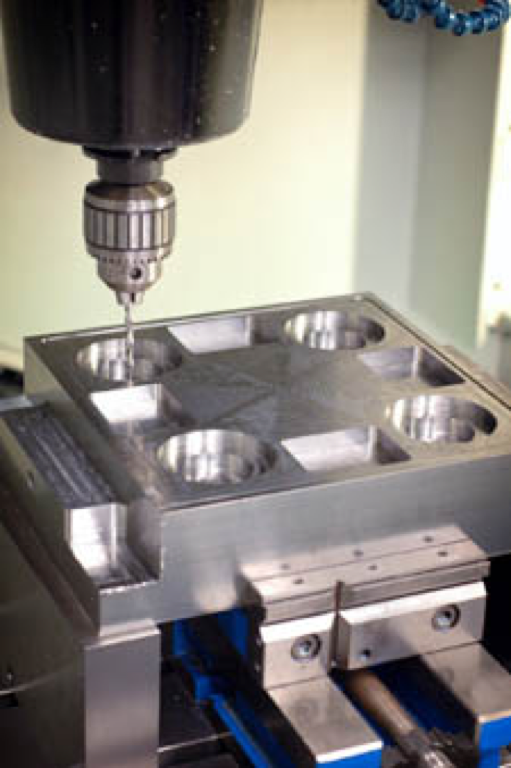

- Mold Base machining

- Mold Cavities machining

Cavities polishing and surface treatment

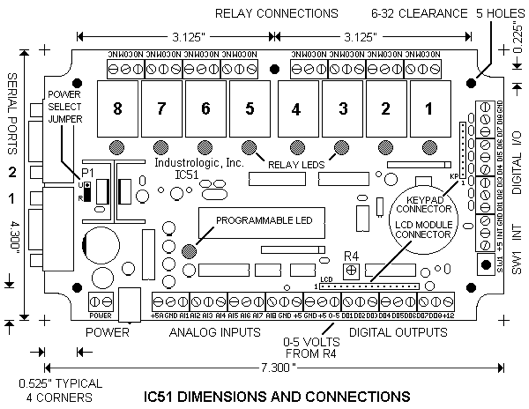

Electronic Design

- Draft of circuit

Components selection

Schematic Design and PCB Layout

- Circuit Test and adjustment

- PCB Layout by appropriate software

Project Programming

- Function analysis

- IC selection

- Program writing and testing.

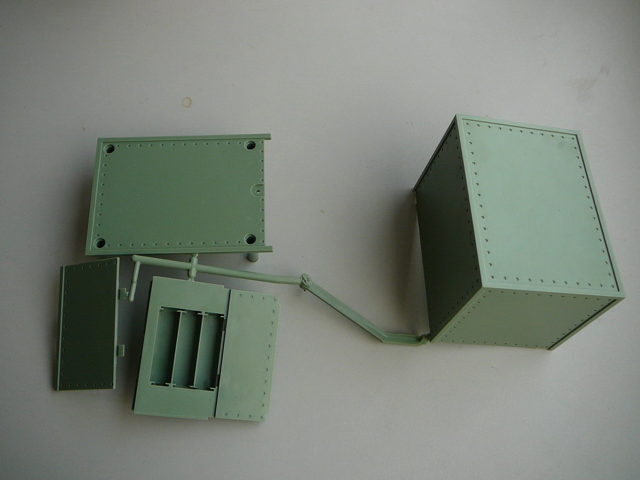

Mold Test Shots

After Molds completed, try test shots on the machine

Record machine parameters in running test shots for future ref

Engineering (EP) samples built from test shots

Check for dimensional accuracy

Sample product performance

Production Pilot

To enhance design of production toolings

2. Efficiency Assessment.

3. Production Quality assessment.

Injection Molding

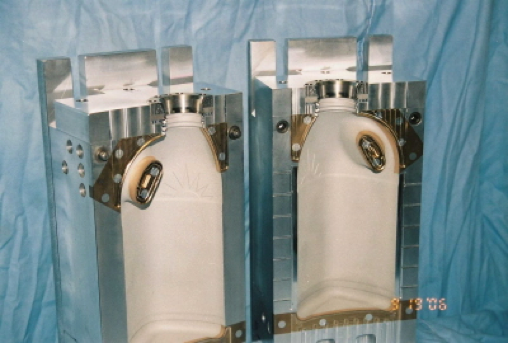

Blow Molding

Roto-casting

Spray Painting

Hand Painting

Tampo Print

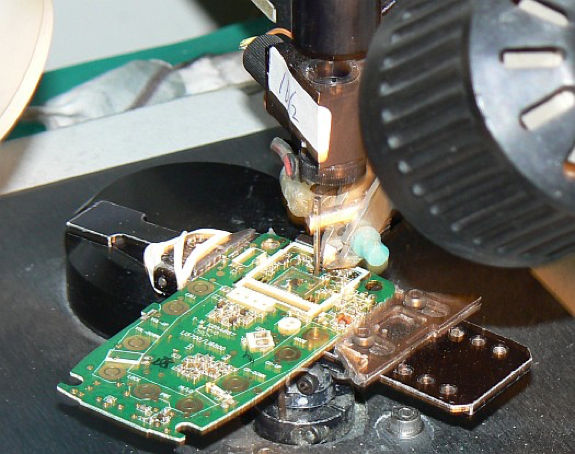

Electronic Components insertion

IC Bonding

PCB assembly (PCBA)

Final Assembly

In-process QC and final product QC

- Quality check will be performed on all functions

Packaging