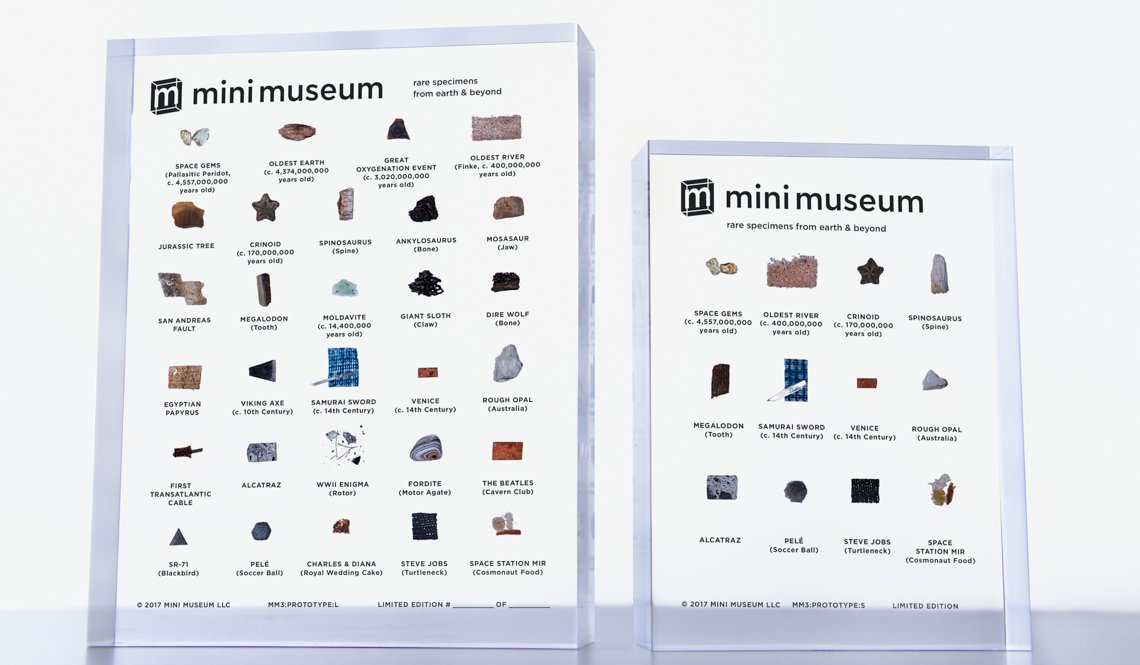

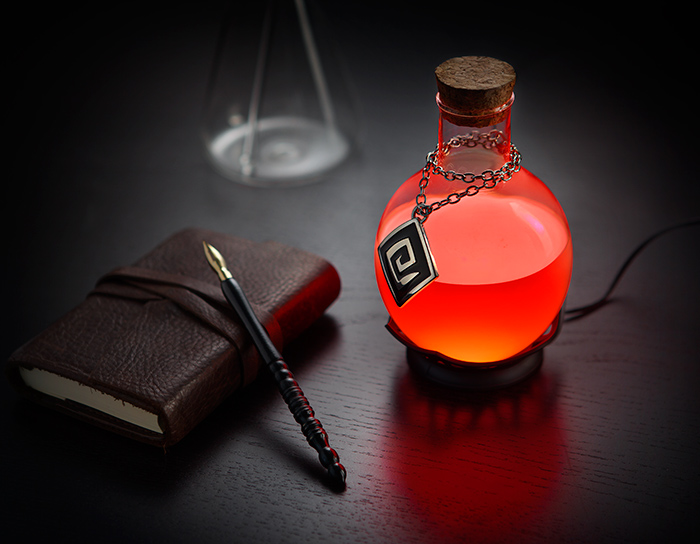

Consumer Products

Founded in 1992, Trendex is a global leader in OEM manufacturing of consumer products that turns your concept into reality. Through extensive experience with manufacturing of license brands, utilizing our own manufacturing facilities and outsource partners, Trendex has provided each customer with an uncompromising commitment to quality and delivery applying cutting edge technology, and highly skilled employees. Our dedicated design team members will work closely with each client to provide you the best solution and lead time which has been proven to be the best in the industry.

We have combined the management skills and the practical skills of the top industry’s companies in a lean manufacturing setting that will assist you with your product design, development, and engineering needs. With new production facility, including prototype development engineering, and design we have now complete product development at one location. We welcome our client to visit and inspect our facility at any time.

OFFERINGS

• Concept Development & Design

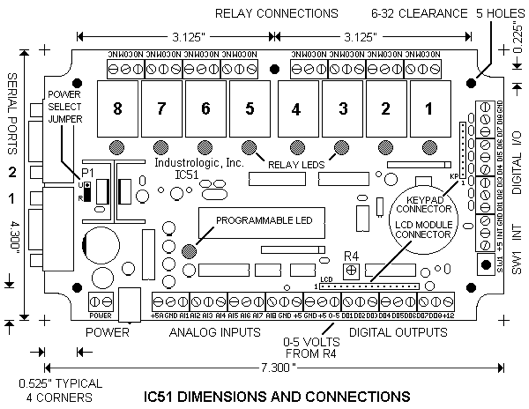

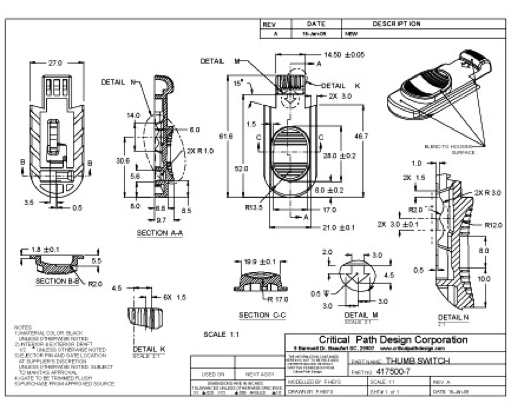

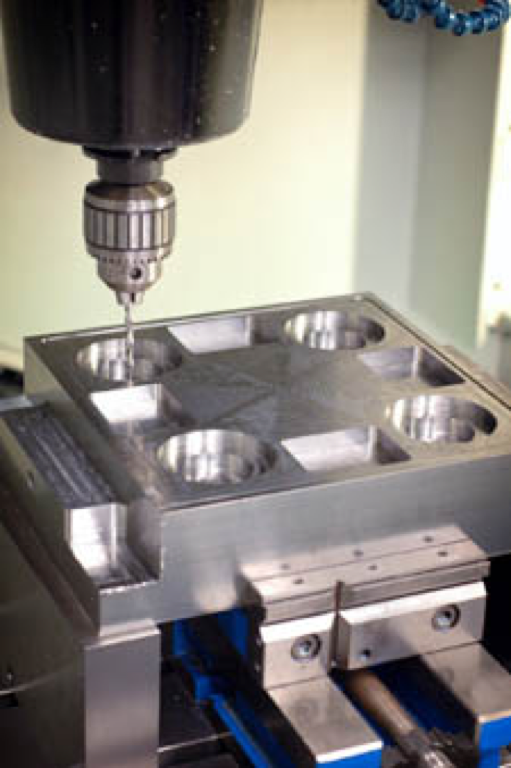

• Mechanical Design

• Industrial Design

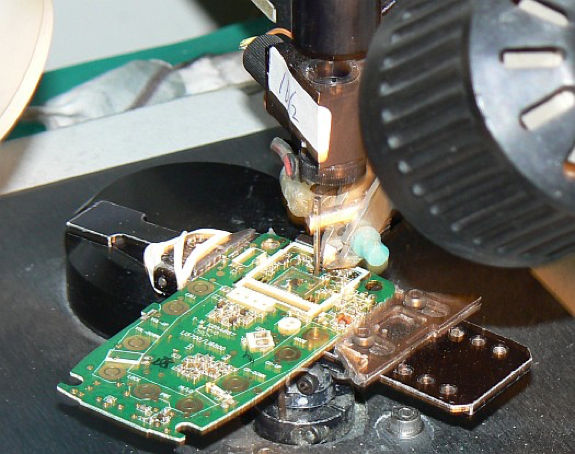

• Electrical Hardware & Software Design

• IC Design

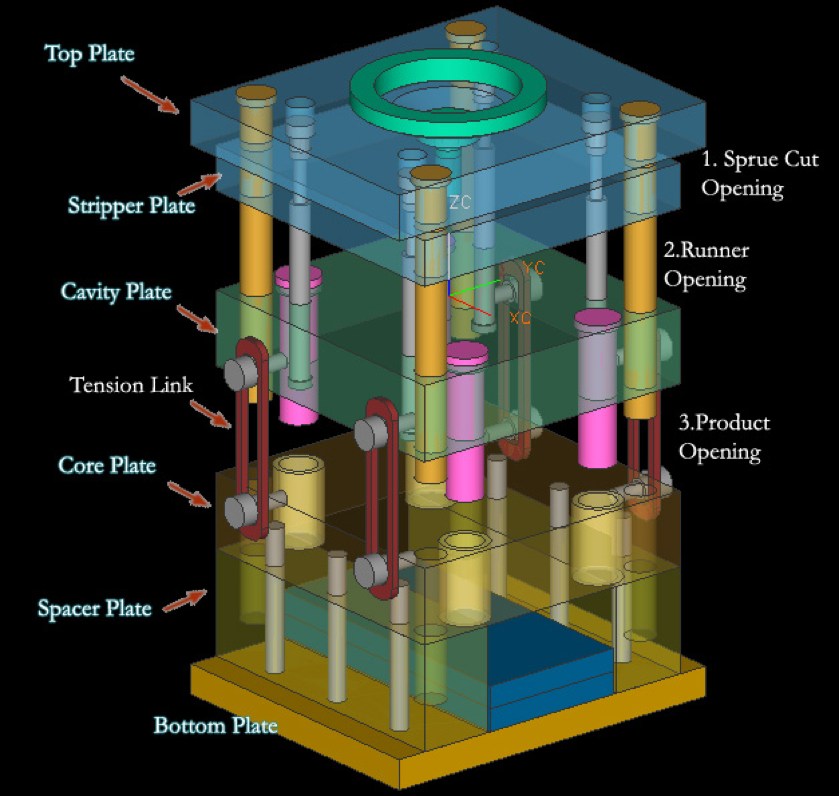

• Production Process Development

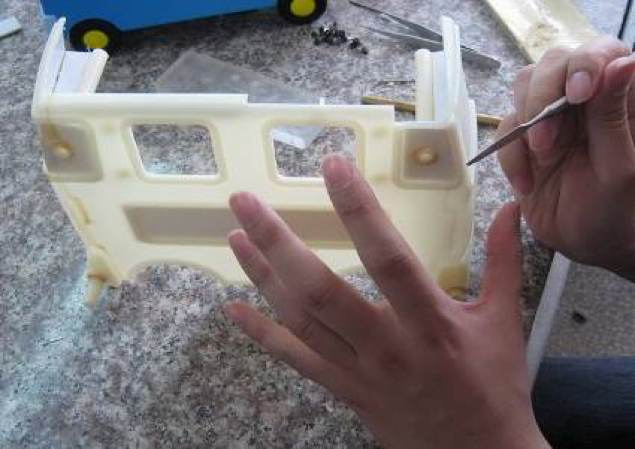

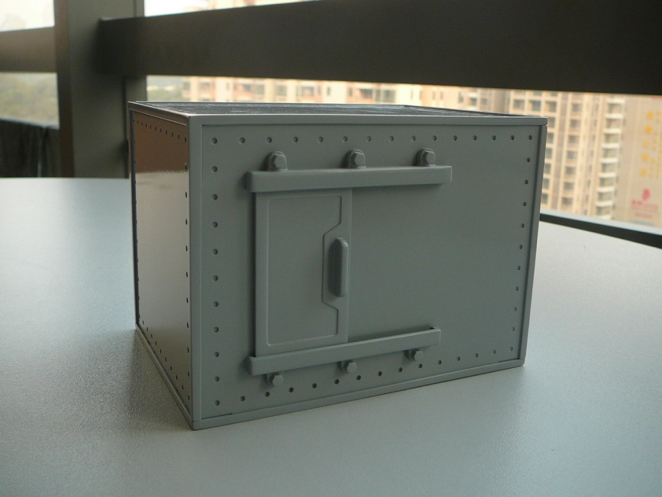

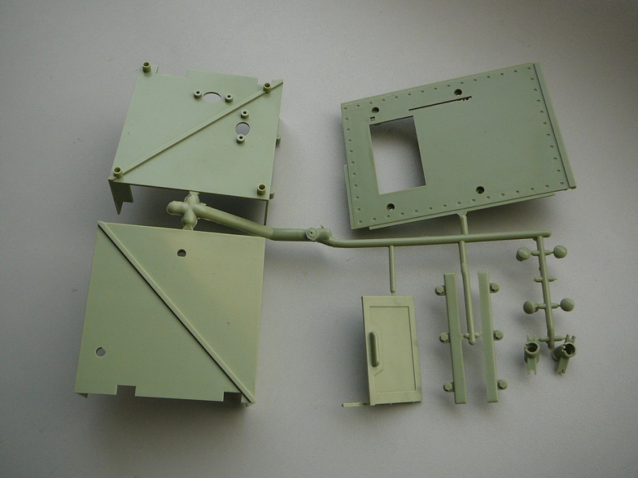

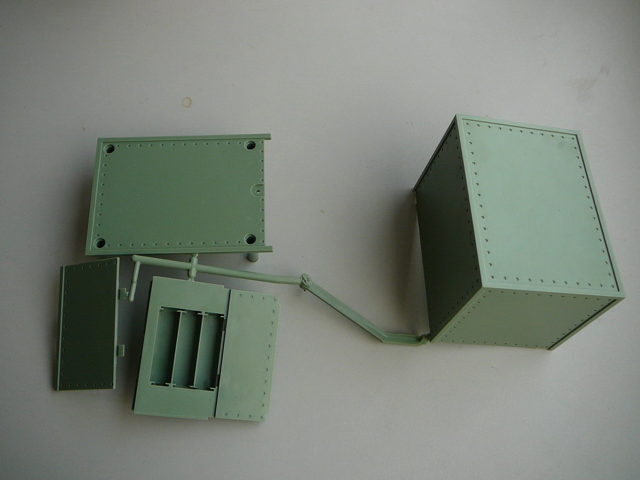

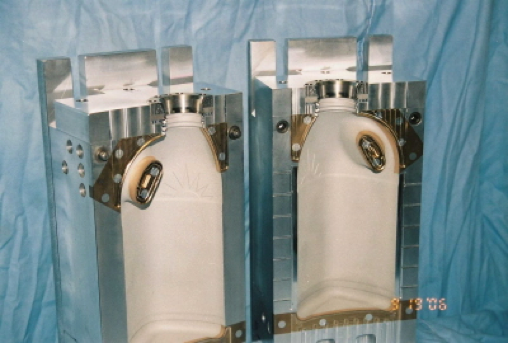

• Prototyping

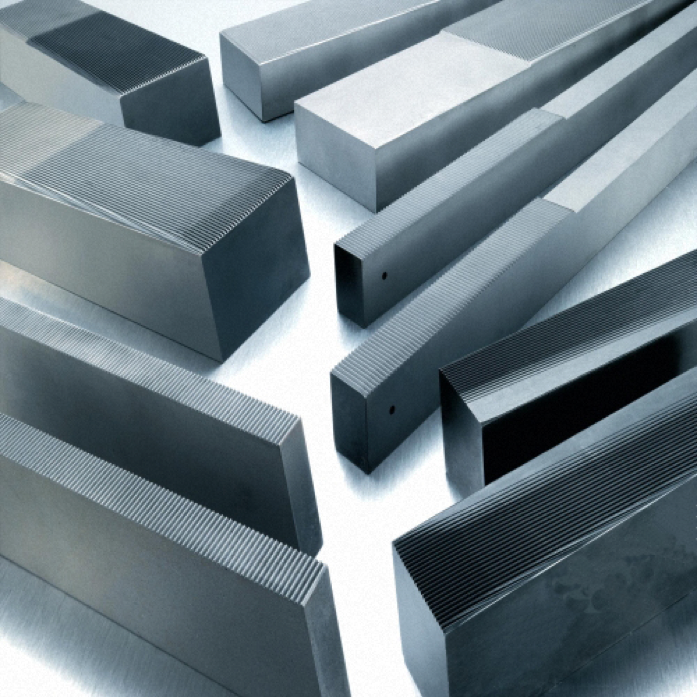

• Tooling

• Package Design

• Production Management

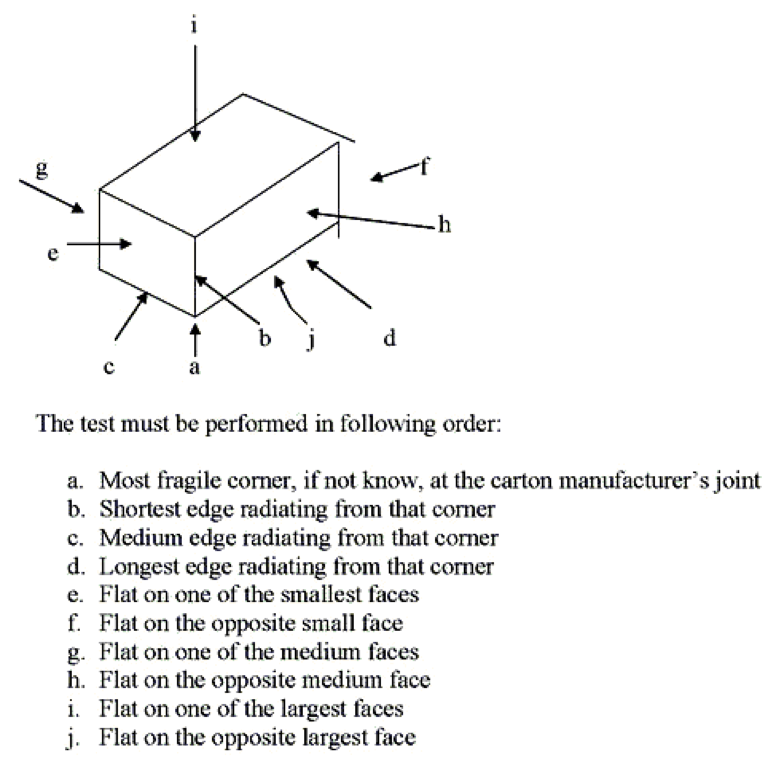

• Product Safety Testing

• Quality Control